International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

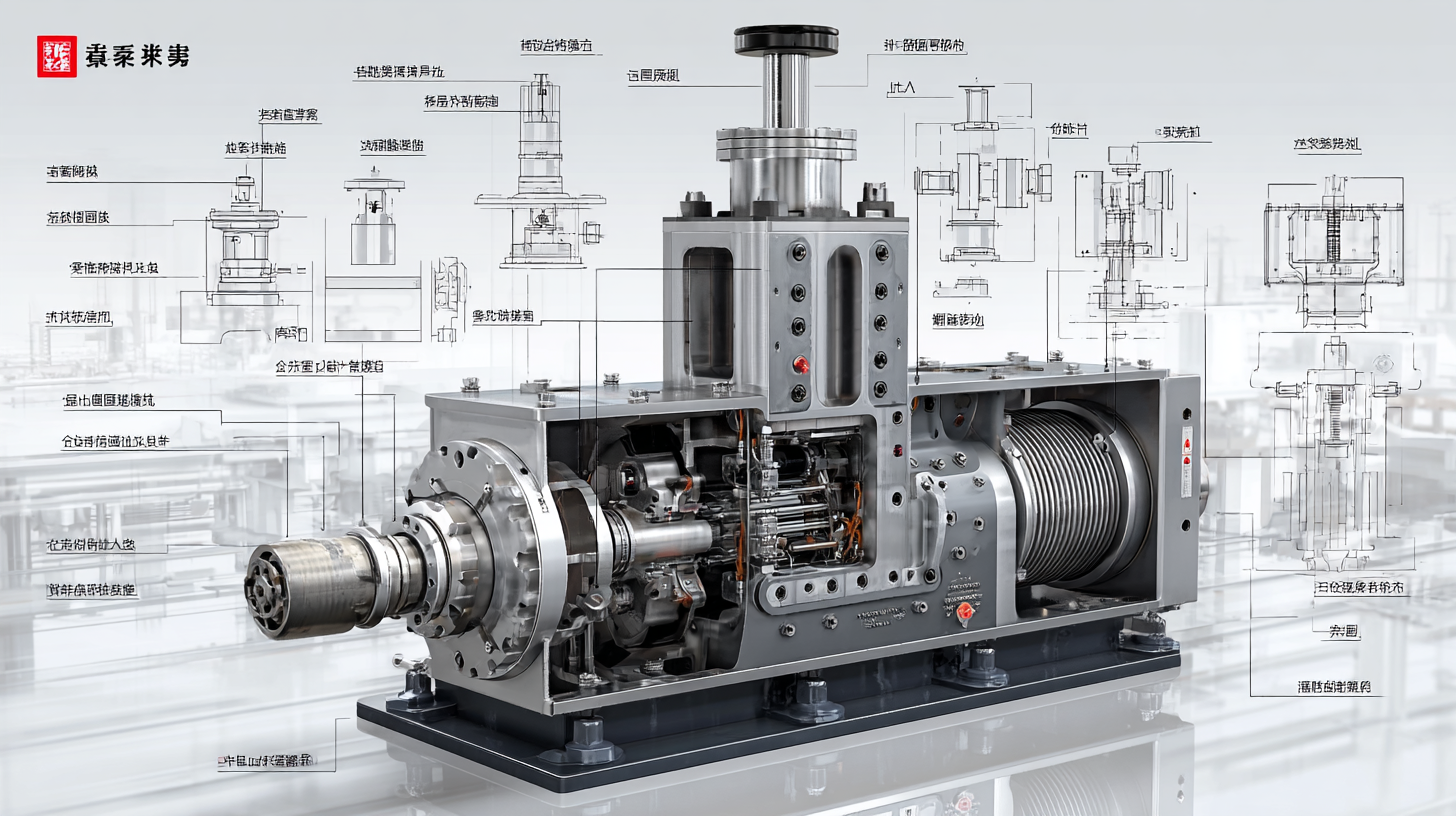

Unleashing China’s Manufacturing Prowess: The Rise of the Best Hydraulic Power Units

In recent years, China's manufacturing industry has rapidly evolved, becoming a powerhouse of innovation and efficiency on the global stage. Central to this transformation is the Hydraulic Power Unit (HPU), a crucial component that powers various industrial applications. As the demand for advanced machinery and systems grows, the HPU's role becomes increasingly significant, driving breakthroughs in sectors such as construction, agriculture, and automotive manufacturing. This blog will explore the various types of Hydraulic Power Units, highlighting their design features, operational efficiencies, and the advantages they bring to modern manufacturing. By understanding the diverse applications and technological advancements of HPUs, we can appreciate how they contribute to China's emergence as a leader in the global manufacturing landscape. Join us as we uncover the key factors that have made hydraulic power units integral to this impressive rise.

The Robust Growth of China’s Hydraulic Power Unit Market: Key Statistics and Trends

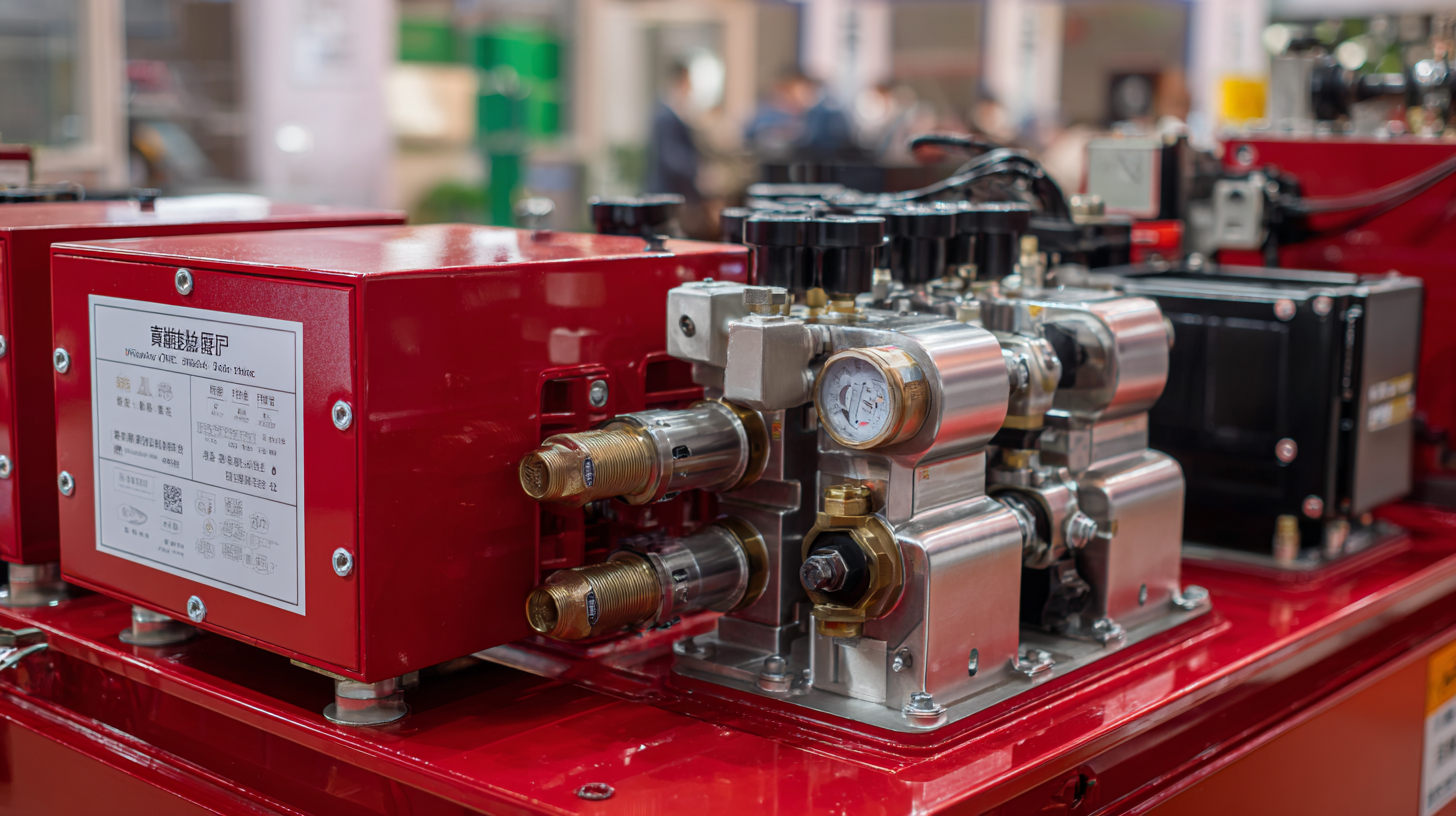

China's hydraulic power unit market is rapidly evolving, showcasing robust growth that taps into the country's advanced manufacturing capabilities. With market size projections indicating significant expansion, China's dominance in hydraulic technology hinges on its well-established supply chains and a booming domestic market. This growth is further catalyzed by strong government support, which continues to foster innovation and efficiency within the sector.

As industries worldwide increasingly prioritize hydraulic systems for their reliability and performance, the statistics reflect an optimistic outlook. The global hydraulic pumps market alone is expected to reach impressive figures in the coming years, underscoring the importance of these units in various applications, from construction to automation. In paralleling this growth, the potential for hydraulic cylinders and fittings also continues to rise, presenting expansive opportunities for manufacturers and suppliers within China. The nation is not only meeting local demand but is also positioning itself as a key player in the global market, further cementing its status as a manufacturing powerhouse.

Assessing the Technological Innovations Driving Hydraulic Power Unit Performance

In recent years, China's manufacturing landscape has undergone a remarkable transformation, particularly in the field of hydraulic power units (HPUs). This shift is driven by a series of technological innovations that have significantly enhanced performance and efficiency. For instance, advancements in digital control systems allow for precise management of hydraulic mechanisms, resulting in smoother operation and reduced energy consumption. These digital innovations also facilitate predictive maintenance, which minimizes downtime and extends the lifespan of hydraulic equipment.

Moreover, the incorporation of advanced materials and smart sensors has further propelled HPU performance. Lightweight yet robust materials improve the overall structural integrity while contributing to energy efficiency. Smart sensors equipped with IoT capabilities enable real-time monitoring and analysis, providing valuable data that can be leveraged for optimizing performance and responsiveness. As these technologies continue to evolve, they not only solidify China’s position as a leader in hydraulic power unit manufacturing but also pave the way for future innovations that can meet the demands of an increasingly automated industrial landscape.

Evaluating the Environmental Impact of Hydraulic Power Units in Manufacturing

The environmental impact of hydraulic power units (HPUs) in manufacturing is a critical area of focus as industries strive to enhance their operational efficiency and sustainability. As hydraulic systems play a pivotal role in various manufacturing processes, understanding their ecological footprint is essential. Recent studies highlight that the energy consumption associated with these units can significantly influence greenhouse gas emissions, particularly when powered by non-renewable energy sources.

For instance, similar investigations into other energy-intensive sectors, such as bitcoin mining, reveal a staggering load capacity factor (LCF) that underscores the strain on local resources, particularly water and energy.

Moreover, the life cycle assessment (LCA) of hydraulic power units can shed light on their environmental impact from production to disposal. This mirrors findings from agriculture, which is identified as a leading contributor to biodiversity loss and greenhouse gas emissions. By adopting cleaner technologies and improving energy efficiency, the manufacturing sector can mitigate these effects.

Innovations in HPUs that reduce energy consumption and promote the use of renewable sources are essential to align with global sustainability goals, as is evident from the ambition of energy sectors worldwide. As the transition to greener manufacturing processes continues, the necessity for a comprehensive environmental evaluation becomes increasingly pressing.

Key Players in China’s Hydraulic Power Unit Sector: Market Share and Competitive Landscape

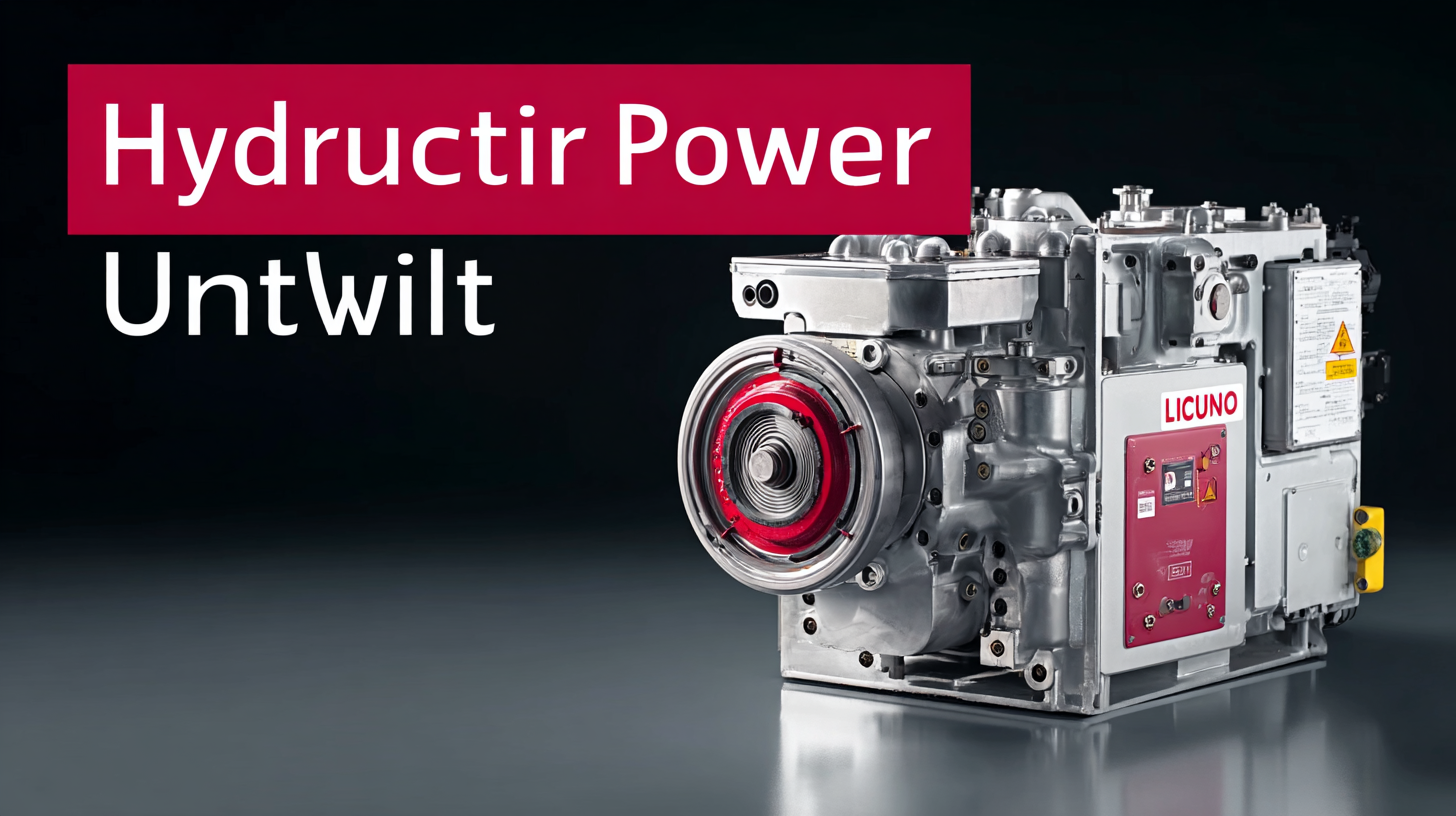

China's hydraulic power unit sector is witnessing significant growth, driven by advancements in technology and increasing demand across various industries. This market is characterized by a competitive landscape that includes several key players, each vying for a larger share of the rapidly expanding market. As companies innovate and enhance their products, factors such as efficiency, durability, and cost-effectiveness are becoming crucial determinants of success. Notably, the integration of smart technologies is also reshaping the market dynamics, as manufacturers strive to meet the needs of modern applications.

The competitive landscape of China's hydraulic power unit market reveals a fascinating array of strategies employed by the leading firms. These players are not only focusing on product quality but are also investing in research and development to maintain their competitive edge. Market share analyses show a strong presence of both domestic and international brands, with each having unique strengths that cater to specific user requirements. The expected growth trajectory, as highlighted in the Vantage Market Research report, indicates that the market will continue to expand, offering opportunities for further innovation and advancement in hydraulic power technology.

Unleashing China’s Manufacturing Prowess: The Rise of the Best Hydraulic Power Units

| Company | Market Share (%) | Revenue (Million USD) | Key Products | Manufacturing Capacity (Units/Year) |

|---|---|---|---|---|

| Company A | 25 | 150 | Hydraulic Pumps, Valves | 5000 |

| Company B | 20 | 120 | Hydraulic Cylinders, Power Units | 4500 |

| Company C | 18 | 100 | Hydraulic Components | 4000 |

| Company D | 15 | 80 | Custom Power Solutions | 3000 |

| Company E | 12 | 60 | Portable Power Units | 2500 |

Future Projections: The Role of Automation in Enhancing Hydraulic Power Unit Efficiency

The rise of automation in various industrial sectors has significantly transformed the efficiency of hydraulic power units in China’s manufacturing landscape. By integrating advanced automation technologies such as IoT devices, machine learning algorithms, and real-time data analytics, manufacturers can enhance the performance and reliability of hydraulic systems. These innovations not only streamline production processes but also minimize energy consumption and reduce operational costs, further establishing China's dominance in the global market.

As automation continues to evolve, the future of hydraulic power units looks promising. Predictive maintenance powered by AI can foresee potential failures, ensuring that hydraulic systems operate at peak performance without unplanned downtime. Furthermore, automated hydraulic systems can adapt to varying workload demands with precision, leading to improved responsiveness and output. This synergy between automation and hydraulic technology is set to redefine how manufacturers approach efficiency and production in the years to come.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.