International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

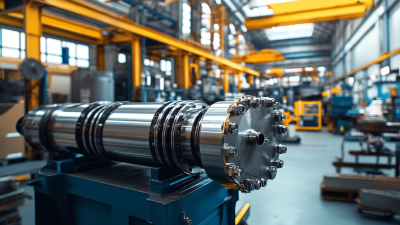

Advantages of Utilizing Small Hydraulic Cylinders in Modern Applications

In today's rapidly evolving industrial landscape, the demand for efficient and compact systems has led to a significant rise in the utilization of Small Hydraulic Cylinders. According to a recent report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach USD 13.4 billion by 2025, with a notable emphasis on miniaturized solutions to meet the growing needs for automation and precision in sectors such as manufacturing, aviation, and robotics. Small Hydraulic Cylinders offer distinct advantages, including their lightweight design, enhanced responsiveness, and the ability to function in confined spaces, making them ideal for modern applications. As industries continue to focus on streamlining processes and improving performance, the integration of these compact hydraulic solutions is proving to be a critical component in driving innovation and efficiency across various sectors.

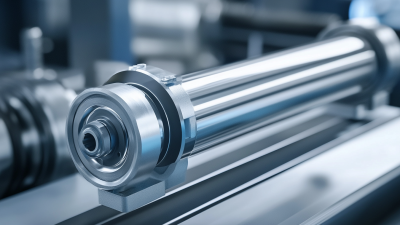

Benefits of Small Hydraulic Cylinders for Space-Constrained Environments

In modern engineering and manufacturing, space constraints often dictate the design and functionality of machinery. Small hydraulic cylinders offer an effective solution in such environments, providing the necessary power while occupying minimal space. These compact components are increasingly being used in applications ranging from automotive engineering to agricultural machinery, where every inch counts. Their ability to generate significant force in tight quarters allows for innovative designs that enhance productivity and efficiency.

When selecting small hydraulic cylinders, consider the following tips: first, assess the application requirements thoroughly. Understanding the force and stroke specifications will help in choosing the right cylinder. Second, prioritize cylinder materials that provide durability while keeping weight low. This is particularly important in mobile applications where weight can affect performance. Lastly, ensure proper installation and maintenance; regular checks can prevent leaks and maintain system efficiency, ultimately extending the lifespan of your equipment.

In addition to their efficiency, small hydraulic cylinders are also notable for their versatility. They can be integrated into various automated systems, boosting operational capabilities without requiring excessive space. Their design can accommodate a multitude of functions, making them an ideal choice for industries seeking innovative solutions in limited environments. By maximizing their use, businesses can achieve significant advancements in both productivity and design flexibility.

Advantages of Utilizing Small Hydraulic Cylinders in Modern Applications

This chart illustrates the benefits of small hydraulic cylinders in space-constrained environments, focusing on key factors such as efficiency, weight capacity, and compactness.

Key Applications of Small Hydraulic Cylinders in Modern Machinery

Small hydraulic cylinders play a crucial role in modern machinery, finding application across various industries such as construction, agriculture, and aerospace. According to a recent market analysis, the global hydraulic cylinder market is projected to reach approximately USD 22 billion by 2027, with a significant share attributed to small hydraulic cylinders. These compact units are characterized by their functionality, typically categorized as either single-acting or double-acting cylinders, each serving distinct operational needs in machinery. The versatility of small hydraulic cylinders allows them to be employed in applications ranging from industrial equipment to mobile devices, contributing to enhanced efficiency and performance.

The demand for small hydraulic cylinders is particularly evident in construction and agricultural sectors, where their compact design and high power-to-weight ratio are paramount. For example, double-acting cylinders, which provide force in both extension and retraction, are indispensable in heavy machinery for lifting and pushing operations. Industry reports suggest that the growing emphasis on automation and smart technology in machinery is further propelling the adoption of advanced hydraulic systems, positioning small hydraulic cylinders at the forefront of innovation in modern engineering solutions.

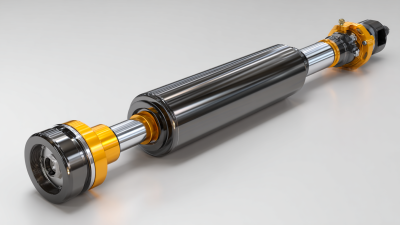

Enhanced Efficiency: How Small Hydraulic Cylinders Improve Performance

The shift toward compact hydraulic systems is revolutionizing modern applications, particularly through the integration of small hydraulic cylinders. These compact solutions not only improve performance but also significantly enhance efficiency in various industries. For instance, advancements in metal additive manufacturing allow for the creation of complex geometries, optimizing flow dynamics while minimizing material usage. This technological evolution contributes to the overall performance of hydraulic systems by ensuring that they operate at high efficiency levels, ultimately reducing energy consumption and material wastage.

As reported, the global automotive hydraulics system market is projected to grow from an estimated USD 43.71 billion in 2023 to expand at a CAGR of 3.9% from 2024 to 2030. This growth reflects the increasing demand for efficient hydraulic components, particularly small cylinders designed for sophisticated applications. Their ability to maintain performance while occupying less space makes small hydraulic cylinders a preferred choice for automotive and construction sectors striving for greater energy efficiency and task flexibility. Through targeted research and development, companies are developing advanced hydraulic systems that meet the industry's heightened requirements for efficiency and performance.

Advantages of Utilizing Small Hydraulic Cylinders in Modern Applications - Enhanced Efficiency: How Small Hydraulic Cylinders Improve Performance

| Feature | Benefit | Application Example |

|---|---|---|

| Compact Design | Easier integration into limited spaces | Robotic arms in manufacturing |

| Lightweight | Lower energy consumption for operation | Construction equipment |

| Precise Control | Enhanced performance in applications requiring accuracy | CNC machines |

| High Power-to-Size Ratio | Increased efficiency relative to size | Automated conveyor systems |

| Versatile Applications | Adapts to various machinery | Material handling and packaging |

Cost-Effectiveness: The Economic Advantages of Small Hydraulic Systems

Small hydraulic cylinders have become increasingly prominent in various modern applications, primarily due to their cost-effectiveness. The economic advantages of these compact systems are significant, especially when compared to larger, more complex hydraulic solutions. Their design enables reduced material costs and lower energy consumption, making them a more attractive option for manufacturers looking to optimize their expenditures without compromising on performance.

Moreover, small hydraulic cylinders are versatile and easily integrated into a range of machinery. Their compact size allows for seamless integration into tight spaces, which can enhance the overall design of equipment and machinery. This flexibility not only streamlines production processes but also reduces the need for additional support structures, thus saving costs in both design and installation. The reduced maintenance requirements and longer lifecycle of these systems further contribute to their economic viability, ensuring businesses can maximize their ROI while leveraging advanced hydraulic technology.

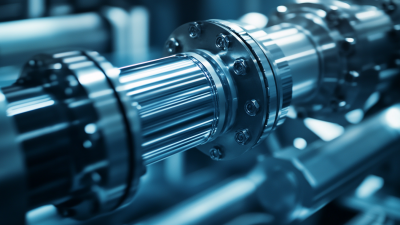

Future Trends: Innovations in Small Hydraulic Cylinder Technology

The future of small hydraulic cylinder technology is poised for significant advancements, driven by the demand for more efficient, compact, and versatile solutions across various industries. As manufacturing and engineering continue to evolve, innovations in materials such as high-strength composites and advanced alloys are set to enhance the durability and performance of these cylinders. These new materials not only reduce the weight of hydraulic systems but also improve their resistance to wear and corrosion, thereby extending service life and reducing maintenance costs.

Furthermore, the integration of smart technologies into hydraulic systems is transforming how small hydraulic cylinders operate. The incorporation of sensors and IoT (Internet of Things) capabilities allows for real-time monitoring and control, leading to improved efficiency and safety. Predictive maintenance software can analyze performance data to foresee potential failures, minimizing downtime and maximizing productivity. As industries increasingly prioritize automation and precision engineering, the role of small hydraulic cylinders equipped with innovative technology will become more critical, paving the way for smarter, more responsive machinery in the future.

Related Posts

-

Innovative Strategies for Sourcing Hyd Cylinders Worldwide

-

Unlocking Global Supply Chain Efficiency with Our Unique Hydraulic Cylinder Catalogue Insights

-

Unleashing Global Potential Small Hydraulic Cylinders from Chinas Leading Manufacturer

-

Exploring the Characteristics and Applications of Best Replacement Hydraulic Cylinders for Global Buyers

-

2025 Insights: How Advanced Materials are Revolutionizing the Best Hydraulic Cylinder Industry

-

Hydraulic Cylinder Tools Trends Shaping the Future of Global Procurement in 2025

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.