International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

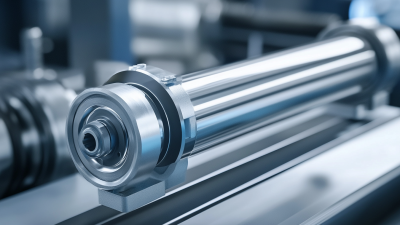

Ultimate Guide to Choosing the Right Hydraulic Cylinder Jack for Your Needs

When it comes to heavy lifting and machinery maintenance, selecting the right Hydraulic Cylinder Jack is critical to ensuring safety and efficiency. According to a report by ResearchAndMarkets, the global hydraulic jacks market is projected to reach $3.42 billion by 2027, driven by increasing demand across various industries, including construction, automotive, and manufacturing. In a landscape where precision and reliability are paramount, understanding the various types of hydraulic jacks available can make all the difference. This guide will explore essential considerations for choosing the right Hydraulic Cylinder Jack to meet your specific needs, taking into account factors such as load capacity, working environment, and maintenance requirements to help you make informed decisions in your applications.

Understanding the Different Types of Hydraulic Cylinder Jacks Available

When it comes to choosing the right hydraulic cylinder jack, understanding the various types available is essential for meeting your specific lifting needs.

There are several categories of hydraulic jacks, each designed for different applications.

Floor jacks, for instance, are perfect for home mechanics working on vehicles, providing stability and ease of use when lifting cars for maintenance or repairs.

Scissor lifts offer a compact design, ideal for jobs requiring vertical lifting in tight spaces, while bottle jacks are portable and suitable for larger loads, making them a versatile option for both automotive and industrial use.

Floor jacks, for instance, are perfect for home mechanics working on vehicles, providing stability and ease of use when lifting cars for maintenance or repairs.

Scissor lifts offer a compact design, ideal for jobs requiring vertical lifting in tight spaces, while bottle jacks are portable and suitable for larger loads, making them a versatile option for both automotive and industrial use.

Moreover, it’s important to consider the recent developments in the hydraulic jack market, such as the new anti-dumping measures imposed on Chinese imports. This could affect the availability and pricing of certain hydraulic jacks, specifically bottle-type jacks. As consumers look for high-quality equipment, understanding the distinctions between types—like off-road jacks suited for rugged terrains versus more general-purpose models—will ensure that you select the right tool for your particular requirements. Each type has its advantages, so knowing their functions and limitations can ultimately make your lifting tasks safer and more efficient.

Key Factors to Consider When Selecting a Hydraulic Cylinder Jack

When selecting a hydraulic cylinder jack, there are several key factors to consider to ensure you choose the right tool for your specific needs. First, assess the weight capacity required for your tasks. Jacks come with varying load limits, and it’s crucial to select one that can safely handle the maximum weight you intend to lift. Additionally, consider the lifting height necessary for your projects; different jacks offer varied stroke lengths, which will affect their overall utility.

Another important aspect is the jack’s construction and material. Look for models that are built with high-quality materials such as steel, as they provide better durability and stability. If you’ll be using the jack in different environments, opting for ones with corrosion-resistant finishes can enhance longevity. Lastly, evaluate the portability of the jack; if you require a device that is easy to move around, lighter models with compact designs may be preferable. Taking into account these factors will help you make an informed decision when choosing a hydraulic cylinder jack to meet your specific requirements.

Top Tips for Ensuring Safety While Using Hydraulic Cylinder Jacks

When using hydraulic cylinder jacks, safety should always be a top priority. According to a recent report by the Occupational Safety and Health Administration (OSHA), improper use of hydraulic jacks contributes to over 30% of workplace injuries related to lifting equipment. To ensure user safety, it’s essential to familiarize yourself with the proper operational techniques and equipment standards.

**Tip 1:** Always inspect your hydraulic jack before each use. Look for any signs of leaks, damages, or corrosion that may compromise its integrity. A study by the American Society of Mechanical Engineers (ASME) revealed that regular maintenance can reduce failure rates by up to 40%, significantly decreasing the risk of accidents.

**Tip 2:** Use the right jack for your specific application. Hydraulic jacks come in various types and weight capacities, so read the manufacturer’s specifications to ensure it meets your needs. Overloading a jack can lead to catastrophic failures, as noted in a review by the International Journal of Safety Engineering that highlighted failed jacks as a primary cause of serious injuries in industrial settings.

**Tip 3:** Always work on stable and level surfaces. A significant amount of hydraulic jack accidents occurs due to unstable footing. Ensure the load is secure before lifting, and never place your body under a lifted load, as this can result in severe injuries or fatalities.

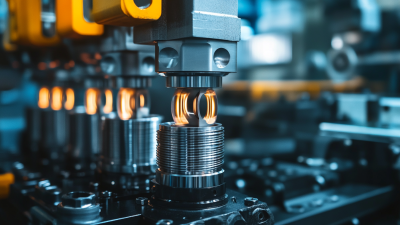

Maintenance and Care Tips for Extending the Life of Your Hydraulic Jack

When it comes to hydraulic cylinder jacks, proper maintenance is crucial for ensuring longevity and optimal performance. According to a report by the American National Standards Institute (ANSI), regular upkeep can extend the life of hydraulic equipment by up to 30%. This underscores the importance of adopting a diligent maintenance routine.

Tip 1: Always check and clean the hydraulic fluid regularly. Dirty or contaminated fluid can significantly reduce the efficiency of your jack and lead to faster wear. A filtration system can help maintain the cleanliness of your hydraulic fluid, improving the jack's performance and lifespan.

Another critical component to consider is the sealing system of your hydraulic jack. Research indicates that nearly 40% of hydraulic failures are attributed to seal wear or damage. Inspect seals for any signs of wear or leaking and replace them as necessary to prevent costly repairs.

Tip 2: Store your hydraulic jack in a clean, dry environment to avoid moisture and debris accumulation. Implement a routine inspection schedule to catch any issues early on. By following these maintenance tips, you can keep your hydraulic jack functioning optimally for years to come.

Real-World Applications: Choosing the Right Jack for Specific Tasks

When it comes to hydraulic cylinder jacks, selecting the right type for specific tasks can greatly enhance efficiency and safety in various applications. For instance, in automotive repair, a low-profile hydraulic jack is often favored due to its ability to fit under vehicles with minimal clearance. This type of jack not only raises the vehicle safely but also provides stability while work is done underneath, making it ideal for tire changes or brake repairs.

In construction and heavy lifting scenarios, a high-capacity hydraulic jack is essential. These jacks are designed to handle significant weight and are often used to lift building materials or heavy machinery. Their robust construction and specific design allow for a wide range of lifting heights, making them versatile tools on job sites. Selecting the appropriate hydraulic jack based on the weight capacity and the nature of the task ensures that operations run smoothly and safely, minimizing downtime and potential accidents.

Ultimate Guide to Choosing the Right Hydraulic Cylinder Jack for Your Needs

| Task | Recommended Cylinder Jack Type | Load Capacity (tons) | Typical Uses |

|---|---|---|---|

| Vehicle Lifting | Bottle Jack | 2-20 | Cars, Trucks |

| Heavy Machinery Maintenance | Floor Jack | 5-50 | Excavators, Loaders |

| Construction Lifting | Scissor Jack | 1-15 | Building Components |

| Transmission Replacement | Telescopic Jack | 3-10 | Vehicles |

| Heavy Load Transport | Pneumatic Jack | 5-30 | Shipping Containers, Heavy Equipment |

Related Posts

-

Unleashing Global Potential Small Hydraulic Cylinders from Chinas Leading Manufacturer

-

Unlocking Efficiency with Mini Hydraulic Cylinders Benefits for Global Buyers

-

Top 10 Electric Hydraulic Power Pack Manufacturers from China at the 137th Canton Fair

-

Exploring the Characteristics and Applications of Best Replacement Hydraulic Cylinders for Global Buyers

-

Hydraulic Piston Repair: Navigating Common Industry Standards and Manufacturing Challenges

-

Understanding the Benefits of Hydraulic Power Packs for Your Business

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.