International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

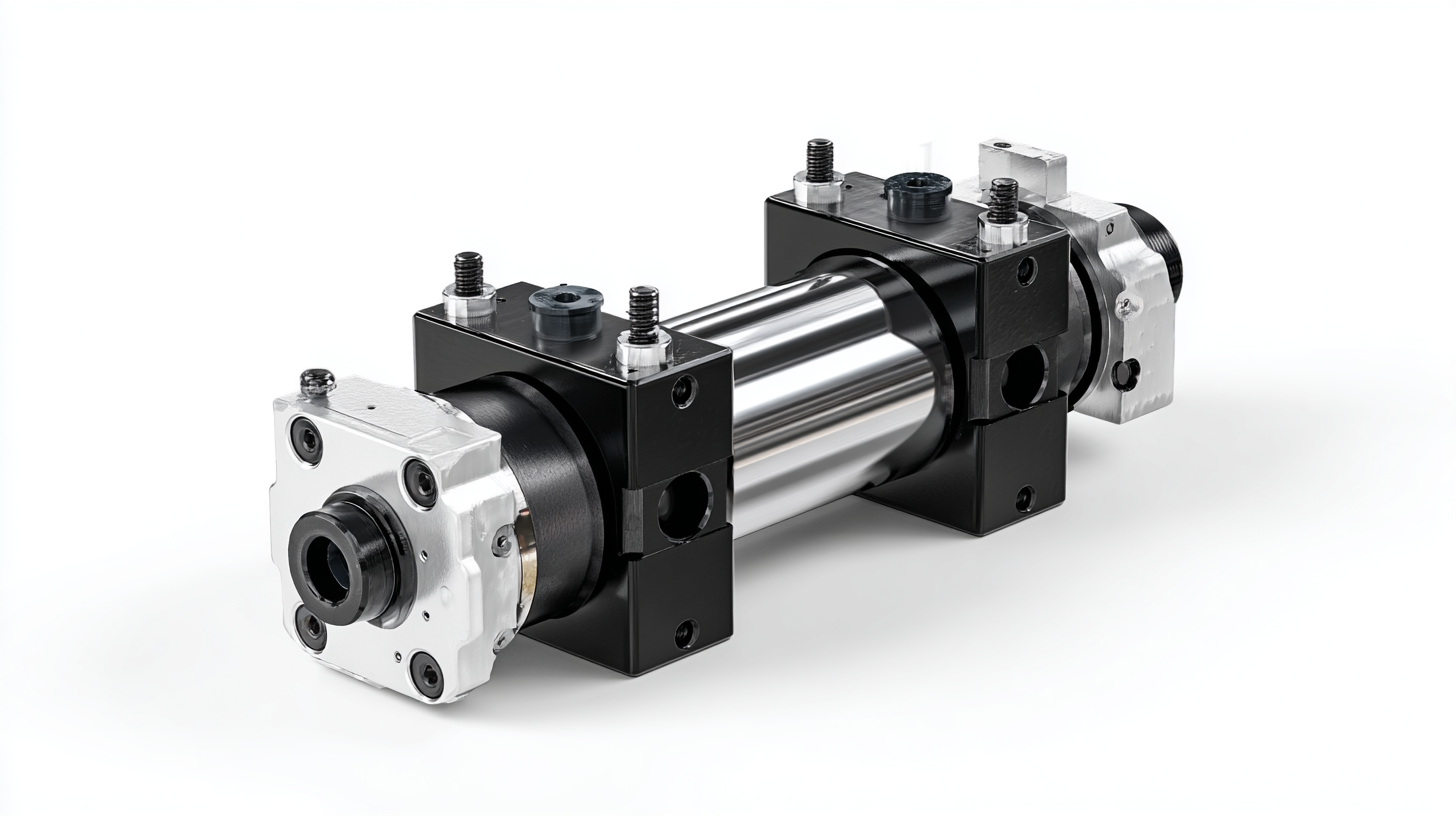

Proudly Crafting World Class Small Hydraulic Cylinders in China for Global Excellence

In today's rapidly evolving industrial landscape, the demand for high-quality small hydraulic cylinders has never been greater. As countries strive for innovation and functionality, China's commitment to crafting world-class hydraulic components stands out as a beacon of excellence. This blog will delve into the intricacies of manufacturing small hydraulic cylinders, showcasing not only the technological advancements that make these products superior but also the tips and strategies that contribute to their global competitiveness. With a focus on precision engineering and quality control, we will explore how Chinese manufacturers are meeting international standards while addressing the unique needs of a diverse clientele. Through our insights, we aim to highlight the vital role these small hydraulic cylinders play in various applications, from automotive to aerospace, and how they are setting the stage for a new era of industrial productivity.

The Future of Hydraulic Cylinder Technology: Trends Shaping 2025

As the hydraulic cylinder industry evolves, significant trends are shaping the future technology landscape by 2025. The global Hydraulic Cylinders market is projected to reach an impressive USD 32.3 billion by 2035, with a CAGR of 5.90%. This growth signals a robust demand for advanced hydraulic solutions in various sectors, including construction and mining, which will be prominently featured at industry events like bauma 2025.

At bauma 2025, attendees can expect to see groundbreaking innovations in hydraulic technologies designed to enhance efficiency and performance. With the construction and mining industries actively incorporating these advancements, the event will showcase five major trends influencing the market. Furthermore, the Work Truck Week 2025 will highlight hydraulic and electrification technologies, indicating a shift towards more versatile and sustainable solutions for work trucks.

Tips for industry professionals looking to stay ahead: invest in understanding the latest hydraulic technology developments and consider attending key exhibitions such as bauma 2025. Networking at these events can provide invaluable insights into market dynamics and prepare your business for future demands. Additionally, keep an eye on market reports that outline growth drivers and emerging trends for strategic planning.

Crafting Excellence: The Art and Science Behind Hydraulic Cylinder Manufacturing

The art and science behind hydraulic cylinder manufacturing are pivotal in achieving global excellence, especially in China's burgeoning hydraulic industry. With a market that is expected to reach $19 billion by 2025, the demand for high-quality hydraulic cylinders is on the rise. Companies in China have committed to integrating cutting-edge technology and stringent quality control measures to meet these demands. Modern production techniques, such as precision machining and advanced material selection, ensure durability and performance under extreme conditions.

When crafting hydraulic cylinders, it’s crucial to focus on precision. A tip for ensuring quality is to invest in advanced CNC machinery that can maintain tolerances within 0.01 mm, significantly enhancing performance and reliability. Additionally, using high-strength materials such as alloy steels can drastically improve the lifespan of hydraulic cylinders, ultimately reducing maintenance costs.

Another important aspect is the testing phase. Implement thorough quality assurance processes to evaluate pressure resistance and leakage rates. According to industry reports, cylinders that undergo rigorous testing experience a 20% reduction in failure rates during operation. This attention to detail not only protects client investments but also reinforces the commitment to manufacturing excellence that defines the Chinese hydraulic cylinder industry.

Global Standards: Ensuring Quality in Small Hydraulic Cylinders

In the rapidly evolving global hydraulic cylinder market, which was valued at approximately USD 14.3 billion in 2021 and is projected to reach USD 18.3 billion by 2027, maintaining high-quality standards is paramount. The emphasis on quality assurance in the production of small hydraulic cylinders is critical to meet the expectations of a competitive marketplace. These compact cylinders are engineered to provide substantial preload capacity, making them essential in various industrial applications where reliability and efficiency are non-negotiable.

Innovative developments, such as the introduction of specialized mini hydraulic cylinders, highlight the industry's commitment to excellence. By adopting global standards in manufacturing processes, companies can ensure their products not only comply with stringent regulations but also outperform competitors. As businesses navigate the complexities of international trade, the focus on quality serves as a cornerstone for fostering trust and establishing a strong foothold in the global market. Thus, the dedication to crafting world-class small hydraulic cylinders in China reflects a broader trend towards excellence that resonates on a global scale.

Proudly Crafting World Class Small Hydraulic Cylinders in China for Global Excellence

This chart depicts the production capacity and quality assurance standards of small hydraulic cylinders manufactured in China compared to global benchmarks over the past five years.

Innovative Materials and Designs: The Next Generation of Hydraulic Cylinders

The hydraulic cylinder industry is poised for transformation with the integration of innovative materials and designs. Advances in composite materials and high-strength steels are paving the way for lighter and more durable hydraulic cylinders, which are crucial for enhancing performance and extending the lifecycle of machinery. According to a recent report by MarketsandMarkets, the global hydraulic cylinders market is expected to reach USD 20.4 billion by 2025, growing at a CAGR of 6.9%. This growth underscores the increasing demand for more efficient hydraulic systems across various sectors, including construction, agriculture, and manufacturing.

One of the most exciting developments in hydraulic cylinder technology is the implementation of smart design principles, which incorporate advanced engineering techniques such as finite element analysis (FEA) and computer-aided design (CAD). These technologies allow manufacturers to optimize cylinder designs for better performance under pressure while minimizing material usage. As the industry shifts towards sustainability, it’s imperative to focus on eco-friendly manufacturing methods and recyclable materials. The adoption of such innovations can not only reduce carbon footprints but also position companies for competitive advantage in a global market that increasingly prioritizes sustainability.

Sustainability in Manufacturing: Eco-Friendly Practices in Hydraulic Cylinder Production

In the pursuit of excellence, the manufacturing of small hydraulic cylinders in China has evolved to embrace sustainability as a core principle. The hydraulic cylinder production process traditionally posed challenges for environmental responsibility; however, innovative manufacturers are now adopting eco-friendly practices that significantly reduce their carbon footprint.

By focusing on energy-efficient machinery, waste reduction techniques, and sustainable sourcing of materials, these companies are not only enhancing their operational efficiency but also contributing positively to the environment.

Adopting a circular economy model, manufacturers are increasingly recycling materials and minimizing waste. For instance, scrap steel from the production process is repurposed, drastically reducing the need for new raw materials and ensuring that valuable resources are utilized to their fullest potential. Moreover, advancements in technology allow for cleaner production methods, which help in lowering emissions and energy consumption. This commitment to sustainability not only aligns with global environmental standards but also appeals to clients seeking responsible supply chain partners, setting a benchmark for hydraulic cylinder manufacturers worldwide.

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.