International Fluid Power Inc.

International Fluid Power - Innovative Partners For Global Sourcing Of Fluid Power Products. Your Complete Hydraulic Source in SE Minnesota.

INTERNATIONAL FLUID POWER, INC.

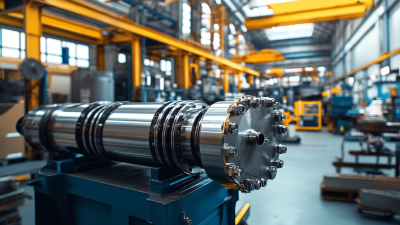

Exploring the Efficiency of Hyd Cylinders: Key Performance Metrics and Industry Insights

The efficiency of hydraulic cylinders, commonly referred to as "hyd cylinders," plays a critical role in various industrial applications, impacting overall system performance and energy consumption. According to the International Fluid Power Society, hydraulic systems can account for up to 20% of energy use in manufacturing processes, highlighting the need for optimized performance metrics in hyd cylinders to enhance operational efficiency. Furthermore, a recent report by the Hydraulic Manufacturers Association indicates that advancements in cylinder technology and design have the potential to improve efficiency by approximately 15% to 30% in specific applications. As industries continue to pursue sustainability and cost-effectiveness, understanding the key performance metrics of hyd cylinders becomes essential for engineers and decision-makers alike. This exploration aims to delve into these metrics while providing industry insights that could inform future innovations and improve overall hydraulic system reliability.

Understanding Hydraulic Cylinder Efficiency: Key Metrics and Their Importance

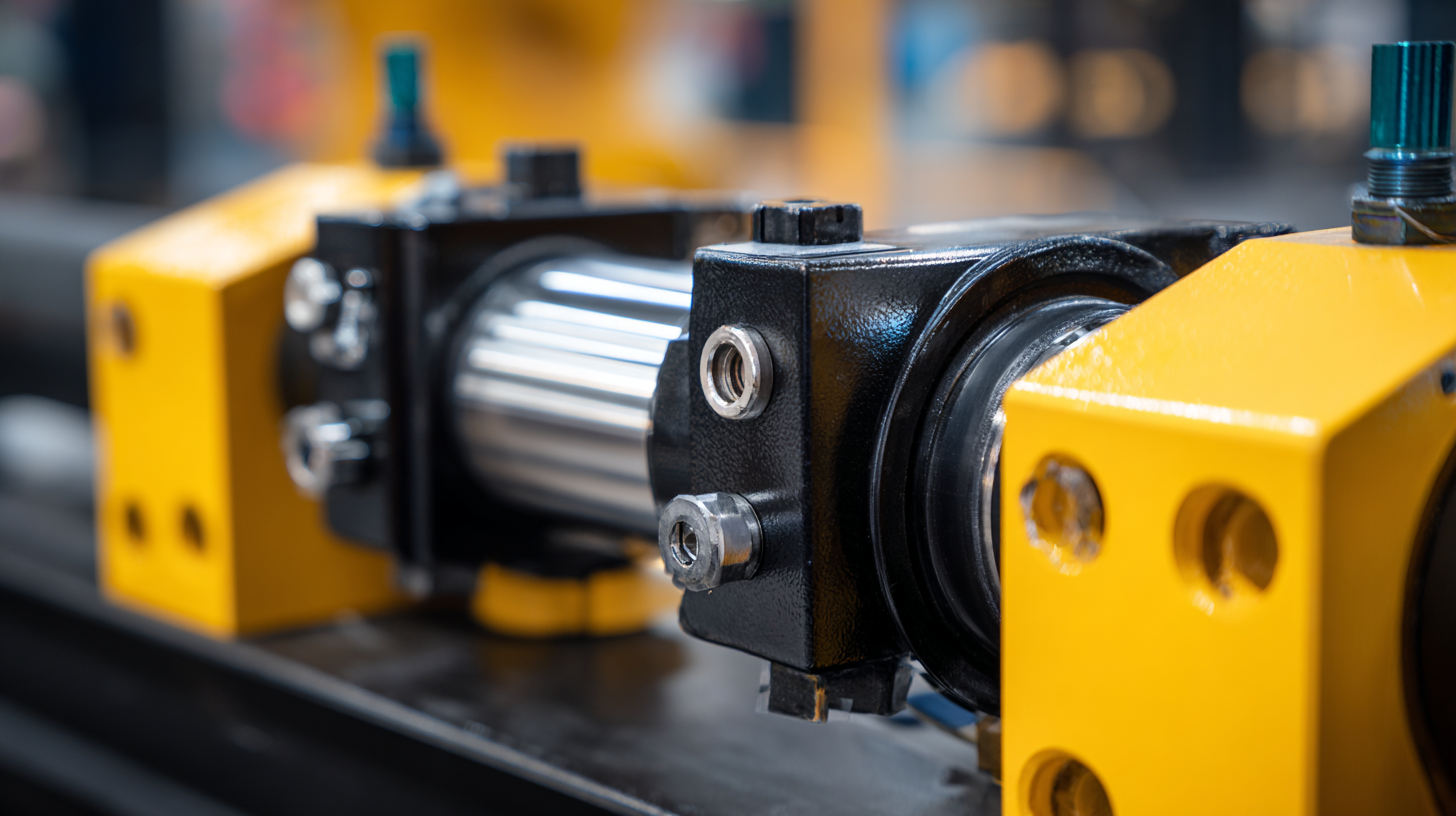

Hydraulic cylinders are crucial components in various industrial applications, powering machinery and enabling precise movement. Understanding hydraulic cylinder efficiency involves examining key performance metrics such as force output, stroke length, and cycle time. These metrics not only determine the effectiveness of the cylinder but also influence the overall productivity and operational costs of hydraulic systems.

Hydraulic cylinders are crucial components in various industrial applications, powering machinery and enabling precise movement. Understanding hydraulic cylinder efficiency involves examining key performance metrics such as force output, stroke length, and cycle time. These metrics not only determine the effectiveness of the cylinder but also influence the overall productivity and operational costs of hydraulic systems.

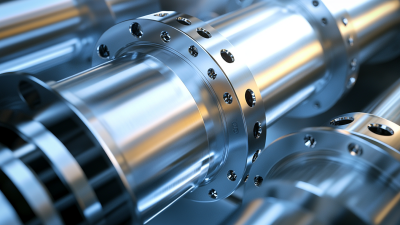

When assessing efficiency, it’s essential to consider the cylinder's design and the materials used. A well-designed hydraulic cylinder can minimize energy loss through leakage or friction, thereby improving overall performance. Regular maintenance is also critical; worn seals or misalignments can lead to reduced efficiency.

Tips: To enhance hydraulic cylinder efficiency, ensure proper alignment during installation, and choose cylinders with high-quality seals. Additionally, monitoring fluid levels and replacing hydraulic fluid at recommended intervals can prevent degradation and improve cylinder lifespan. Regularly assessing performance metrics against industry benchmarks can provide valuable insights for optimization.

Top Performance Indicators for Hydraulic Cylinders: Strength, Speed, and Precision

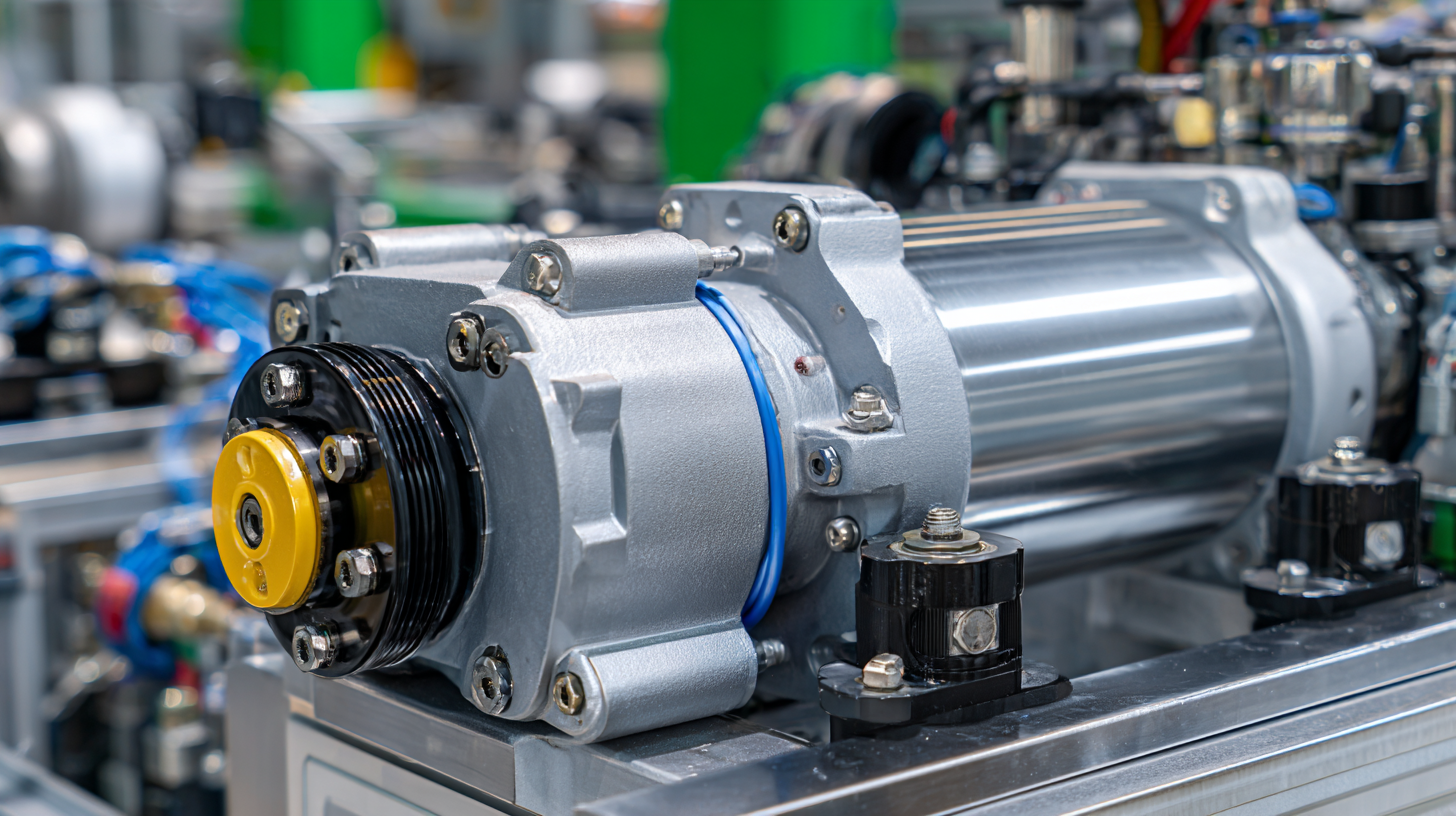

Hydraulic cylinders are pivotal in various industrial applications, and understanding their key performance indicators—strength, speed, and precision—can greatly enhance operational efficiency. Recent analysis indicates that the strength of hydraulic cylinders can impact load-bearing capacities significantly. For instance, utilizing advanced materials and innovative design techniques can increase pressure ratings by up to 30%, enabling them to handle more demanding tasks. Furthermore, the versatility in applications requires cylinders that adapt quickly to operational speeds; research suggests that optimizing speed settings can improve cycle times by 20% in high-demand scenarios.

**Tips:** When selecting hydraulic cylinders, consider the specific requirements of your application. Analyze the load and pressure requirements meticulously to ensure longevity and performance. Additionally, precision in movement is crucial; investing in technology that integrates automatic control systems can lead to enhanced accuracy in operations.

Precision is further being prioritized in the design of hydraulic systems. Innovations, like servo electric cylinders in CNC machines, demonstrate significant advancements in control and accuracy. Reports highlight that CNC rolling operations can see improvements in precision by 15%, minimizing errors and wastage. Implementing such advanced technologies not only boosts performance but also aligns with industry trends toward sustainable and efficient manufacturing practices.

Efficiency Metrics of Hydraulic Cylinders

Evaluating Energy Consumption in Hydraulic Cylinder Systems: Industry Averages and Best Practices

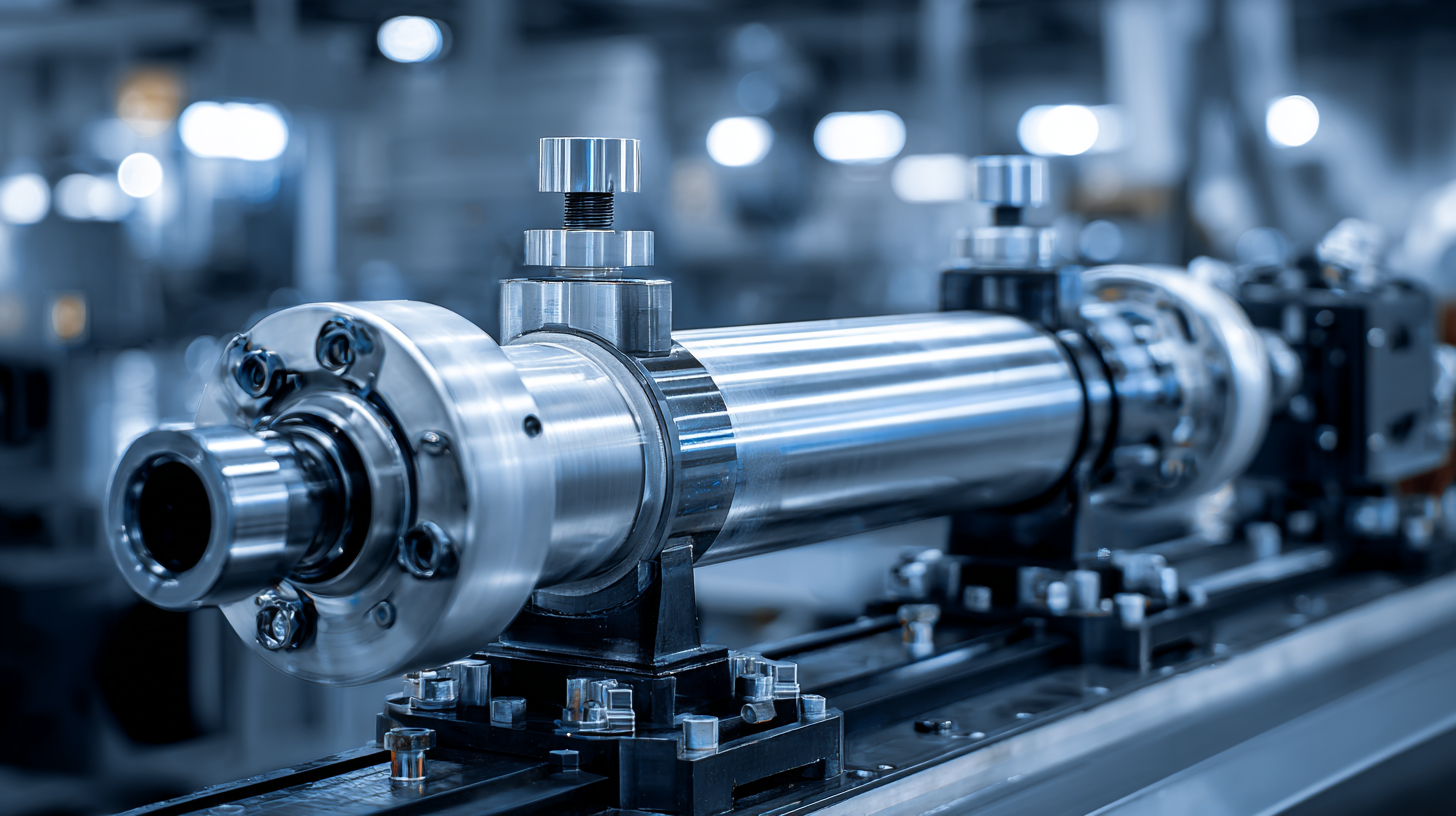

Hydraulic cylinders are essential components in various industrial applications, and understanding their energy consumption is critical for optimizing performance. Recent evaluations of hydraulic systems have shown that energy efficiency can be significantly improved through targeted technological measures. For instance, studies on elliptical gear hydraulic pumps have demonstrated enhanced performance when evaluated with systematic methodologies, which can inform best practices in the industry.

To further optimize the energy use of hydraulic cylinder systems, it is beneficial to implement industry-average benchmarks. By assessing energy consumption patterns and comparing them against these benchmarks, managers can identify potential areas for improvement.

**Tips**: Consider conducting regular energy audits of hydraulic systems to pinpoint inefficiencies. Additionally, exploring the latest energy-efficient technologies can lead to significant cost savings and reduced operational expenses. Engaging in continuous training for plant managers on best practices also ensures that the workforce remains adept at implementing energy-saving strategies effectively.

Innovative Techniques for Enhancing Hydraulic Cylinder Performance: Case Studies and Success Factors

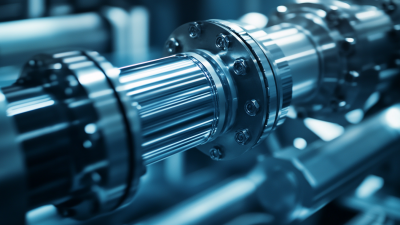

Innovations in hydraulic cylinder technology

are transforming the landscape of industrial applications. According to a recent report from the International Hydraulics Association (IHA), implementing advanced design techniques can enhance the efficiency of hydraulic systems by up to 30%. Techniques such as using advanced seal materials and optimizing cylinder geometry have proven crucial in achieving these performance gains. Various case studies highlight how companies that adopted these innovations saw significant reductions in operational downtime and maintenance costs.

Tips: Always evaluate the compatibility of new materials with existing hydraulic fluids to prevent degradation and ensure longevity. Regular inspections are crucial to identify potential leaks and performance issues before they escalate.

Another successful strategy in enhancing hydraulic cylinder performance is the application of IoT (Internet of Things) technology for predictive maintenance. By integrating sensors with hydraulic systems, companies can monitor real-time performance and receive alerts on impending failures. The IHA reports that organizations utilizing smart technology for maintenance can experience a decrease in unexpected equipment failures by over 40%. This proactive approach not only boosts operational efficiency but also prolongs the lifespan of hydraulic cylinders.

Tips: Invest in training for your team to effectively analyze data from IoT devices. Understanding this information can lead to informed decisions that optimize performance even further.

Future Trends in Hydraulic Cylinder Technology: Insights from Industry Experts and Forecasts

The hydraulic cylinder market has shown significant growth potential, with a valuation of $10.94 billion in 2018 and projected to reach $19.77 billion by 2032, reflecting a compound annual growth rate (CAGR) of 4% over this period. This growth underscores the increasing demand for hydraulic cylinders across various industries, including aerospace and automotive, where precision and reliability are paramount. Industry experts predict that advancements in hydraulic technology will drive efficiency and performance, enabling manufacturers to meet the evolving needs of the market.

Future trends in hydraulic cylinder technology are focused on innovation and sustainability. As manufacturers prioritize energy-efficient solutions, the introduction of smart hydraulic systems integrated with IoT capabilities is expected to enhance operational efficiency and reduce maintenance costs. Reports indicate that the automation of hydraulic operations, particularly in sectors like metal fabrication and pipeline welding, will play a crucial role in the industry's evolution. Furthermore, there is a growing emphasis on developing environmentally friendly hydraulic fluids, which will contribute to safer operations and reduced environmental impact as companies adapt to global sustainability goals.

Exploring the Efficiency of Hyd Cylinders: Key Performance Metrics and Industry Insights

| Metric | Value | Industry Standard | Future Trend |

|---|---|---|---|

| Max Operating Pressure | 3000 PSI | 2500 PSI | Increased to 3500 PSI |

| Cycle Speed | 50 mm/s | 40 mm/s | Optimizations for 60 mm/s |

| Efficiency Ratio | 92% | 85% | Target of 95% |

| Lifespan | 15000 hours | 12000 hours | Projected 20000 hours |

| Weight | 50 kg | 60 kg | Trend towards lightweight materials |

Related Posts

-

Hydraulic Cylinder Tools Trends Shaping the Future of Global Procurement in 2025

-

Solutions for Optimal Hydraulic Cylinder Tools Efficiency

-

Innovative Strategies for Sourcing Hyd Cylinders Worldwide

-

Unlocking Global Supply Chain Efficiency with Our Unique Hydraulic Cylinder Catalogue Insights

-

7 Tips for Finding the Perfect Used Hydraulic Cylinders for Your Business Needs

-

Innovative Applications of Stainless Steel Hydraulic Cylinders in Modern Machinery

You Can Find International Fluid Power Here:

Search For:

Footer #4 Widget

This is an example of a widget area that you can place text to describe a product or service. You can also use other WordPress widgets such as recent posts, recent comments, a tag cloud or more.

© 2025 International Fluid Power, Inc. All Right Reserved.